|

|

|

|

|

Mixing Vessels, Tanks & Pipes |

||

| Click on any picture for a larger view. | ||

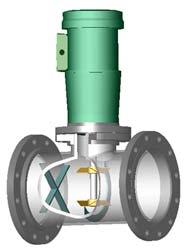

PipesPipeline Mixers, Pipe Mixer, In-line Mixing, Line Mixers, Line Blenders, Process Intensifiers These mixing containers are installed right in the pipeline. Ideal for continuous processes or when a fluid component must be intensely mixed prior to injection or addition into another mixing vessel. This is not limited to just miscible fluids, but can also handle liquid-liquid dispersions, gas-liquid mass transfer, or solids dissolution. Its a great way to mix high viscosity fluids, that are already being transported through a pipeline. |

Example of a pipe being the mixing vessel. Illustration by P. Csiszar |

|

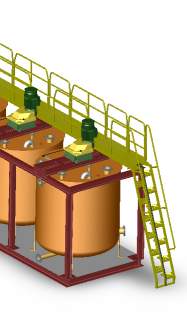

Vertical tanksThese are tanks standing upright. Mixers are most often mounted as top entering or bottom entering, where they are mounted centrally on the base or top head of the reactor. Some mixers are mounted on the heads, but off to the side. Most common bottom entry off-center mounted mixers are the magnetic mixers. Most common versions for top entry are off-center shafts parallel to the tank walls (eccentric mixers), or angled toward the center as is the case with most portable mixers. |

Example of a top entry mixer on a vertical tank. Illustration by P. Csiszar |

|

Cylindrical tanksMost common form of mixing vessel or chemical reactor in all of the process industries. If nothing else is mentioned about a mixing tank, most likely a metal vertical cylindrical tank is considered, fully baffled. There are several types of heads on cylindrical tanks.

Here is an example of a glass-lined vertical tank that has been cut-out to show the interior. It has a C-baffle and a pH-probe and 3 impellers all made of glass-lined steel. |

Example of a top entry mixer on a glass-lined vertical tank. Courtesy of Jürgen Reinemuth |

|

Square tanksOften square tanks are used based on materials of construction and expense. Square tanks are often cheaper to build than cylindrical tanks. They are common in phosphoric acid production, waste water treatment, and older mineral solvent extraction plants. Often people erroneously assume that because the walls are square, baffles are not needed. This is true for up to about 0.5 Hp/1000 gallons or 0.1 kW/m3. Above that and you need baffles to stop the swirl. |

Example of a square tank made of cement for a copper solvent extraction process. |

|

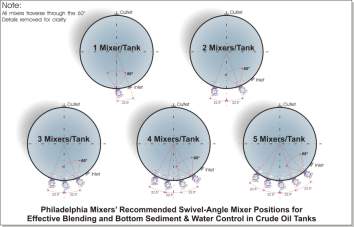

Vertical tanks with side-entry mixersAnother common mixer mounting practice is called side entering mixing. Here the mixer is mounted on the tank walls, mostly near the base of the tank. The petroleum and flood oil industry uses many of these, typically with just one mixer per tank. Flue Gas Desulfurization (FGD) often has 3 or more mixers per tank, either located all on one side (cluster arrangement) or evenly spaced around the tank perimeter (symmetrical arrangement). Side entry mixers can also be used in waste water treatment. They are typically found in large volume squat tanks, where top entry would be impractical. |

Examples of a side-entry mixer and orientation rules for the mounting of side-entry mixers on a tank as a function of the number of mixers. Courtesy of Philadelphia Mixers |

|

Horizontal tanksCylindrical tanks are most common with dished heads. They are commonly under pressure. In the mining industry they call these types of vessels autoclaves. Autoclave reactors often have chambers inside of the tank, each having one to three agitators, so that this continuous process mixer behaves as several continuous stirred tank reactors (CSTR) in series. These types of vessels can also be found skid-mounted or on a trailer and pulled or transported by trucks. |

|

|

|

|